公告版位

目前分類:刀具加工知識大百科 (41)

- Apr 21 Sun 2013 15:24

鋁合金的加工切削特性

- Jan 18 Fri 2013 16:37

鎢鋼材質牌號性能對照表

| 合金 牌號 |

ISO國際標準 | 密度g/cm2 | 抗彎強度不低於N/cm2 | 硬度不低於 HRA |

加工條件及用途 |

| YG3X | K01 | 14.6-15.2 | 1320 | 92 | 適於鑄鐵、有色金屬及合金淬火鋼合金鋼小切削斷面高速精加工。 |

| YG6A | K05 | 14.6-15.0 | 1370 | 91.5 | 適於硬鑄鐵,有色金屬及其合金的半精加工,亦適於高錳鋼、淬火鋼、合金鋼的半精加工及精加工。 |

| YG6X | K10 | 14.6-15.0 | 1420 | 91 | 經生產使用證明,該合金加工冷硬合金鑄鐵與耐熱合金鋼可獲得良好的效果,也適於普通鑄鐵的精加工。 |

| YK15 | K15 K20 |

14.2-14.6 | 2100 | 91 | 適於加工整體合金鑽、銑、鉸等刀具。具有較高的耐磨性及韌性。 |

| YG6 | K20 | 14.5-14.9 | 1380 | 89 | 適於用鑄鐵、有色金屬及合金非金屬材料中等切削速度下半精加工。 |

| YG6X-1 | K20 | 14.6-15.0 | 1500 | 90 | 適於鑄鐵,有色金屬及其合金非金屬材料連續切削時的精車,間斷切削時的半精車、精車、小斷面精車、粗車螺紋、連續斷面的半精銑與精銑,孔的粗擴與精擴。 |

| YG8N | K30 | 14.5-14.8 | 2000 | 90 | 適於鑄鐵、白口鑄鐵、球墨鑄鐵以及鉻、鎳不銹鋼等合金材料的高速切削。 |

| YG8 | K30 | 14.5-14.9 | 1600 | 89.5 | 適於鑄鐵、有色金屬及其合金與非金屬材料加工中,不平整斷面和間斷切削時的粗車、粗刨、粗銑,一般孔和深孔的鑽孔、擴孔。 |

| YG10X | K35 | 14.3-14.7 | 2200 | 89.5 | 適於製造細徑微鑽、立銑刀、旋轉銼刀等。 |

| YS2T | K30 | 14.4-14.6 | 2200 | 91.5 | 屬超細顆粒合金,適於低速粗車,銑削耐熱合金及鈦合金,作切斷刀及絲錐、鋸片銑刀尤佳。 |

| YL10.1 | K15-K25 | 14.9 | 1900 | 91.5 | 具有較好的耐磨性和抗彎強度,主要用為生產擠壓棒材,適合做一般鑽頭、刀具等耐磨件。 |

| YL10.2 | K25-K35 | 14.5 | 2200 | 91.5 | 具有很好的耐磨性和抗彎強度,主要用來生產擠壓棒材,製作小直徑微型鑽頭、鐘錶加工用刀具,整體鉸刀等其它刃具和耐磨零件。 |

| YG15 | 13.9-14.2 | 2100 | 87 | 適於高壓縮率下鋼棒和鋼管拉伸,在較大應力下工作的頂鍛、穿孔及衝壓工具。 | |

| YG20 | 13.4-13.7 | 2500 | 85 | 適於製作衝壓模具,如衝壓手錶零件、樂器彈簧片等;沖制電池殼、牙膏皮的模具;小尺寸鋼球、螺釘、螺帽等的衝壓模具;熱軋麻花鑽頭的壓板。 | |

| YG20C | 13.4-13.7 | 2200 | 82 | 適於製作標準件、軸承、工具等行業用的冷鐓、冷沖、冷壓模具;彈頭對彈殼的衝壓模具。 | |

| YT15 | P10 | 11.0-11.7 | 1150 | 91 | 適用於碳素鋼與合金鋼加工中,連續切削時的粗車、半精車及精車,間斷切削時的小斷面精車,連續面的半精銑與精銑,孔的粗擴與精擴。 |

| YT14 | P20 | 11.2-12.0 | 1270 | 90.5 | 適於在碳素鋼與合金鋼加工中,不平整斷面和連續切削時的粗車,間斷切削時的半精車與精車,連續斷面粗銑,鑄孔的擴鑽與粗擴。 |

| YT5 | P30 | 12.5-13.2 | 1430 | 89.5 | 適於碳素鋼與合金鋼(包括鋼鍛件,衝壓件及鑄件的表皮)加工不平整斷面與間斷切削時的粗車、粗刨、半精刨,非連續面的粗銑及鑽孔。 |

| YS25 | P20、P40 | 12.8-13.2 | 2000 | 91 | 適應於碳素鋼、鑄鋼、高錳鋼、高強度鋼及合金鋼的粗車、銑削和刨削。 |

| YS30 | P25 P30 |

12.45 | 1800 | 91 | 屬超細顆粒合金,適於大走刀高效率銑削各種鋼材,尤其是合金鋼的銑削。 |

| YW1 | M10 | 12.6-13.5 | 1180 | 91.5 | 適於耐熱鋼、高錳鋼、不銹鋼等難加工鋼材及普通鋼和鑄鐵的加工。 |

| YW2 | M20 | 12.4-13.5 | 1350 | 90.5 | 適於耐熱鋼、高錳鋼、不銹鋼及高級合金鋼等特殊難加工鋼材的精加工,半精加工。普通鋼材和鑄鐵的加工。 |

| YT15 | P10 | 11.0-11.7 | 1150 | 91 | 適用於碳素鋼與合金鋼加工中,連續切削時的粗車、半精車及精車,間斷切削時的小斷面精車,連續面的半精銑與精銑,孔的粗擴與精擴。 |

| YT14 | P20 | 11.2-12.0 | 1200 | 90.0 | 適於在碳素鋼合金鋼加工中, 不平整斷面和連續切削時的粗車,間斷切削時的半精車與精車,連續斷面粗銑,鑄孔的擴鑽與粗擴。 |

| YT5 | P30 | 12.5-13.2 | 1400 | 89.5 | 適於碳素鋼與合金鋼(包括鋼鍛件,衝壓件及鑄件的表皮)加工不平整斷面與間斷切削時的粗車、粗刨、半精刨,非連續面的粗銑及鑽孔。 |

| YS30 | P25 P30 |

12.45 | 1800 | 91.0 | 屬超細顆粒合金,適於大走刀高效率銑削各種鋼材,尤其是合金鋼的銑削。 |

| YS25 | M20、M30P20、P40 | 12.8-13.2 | 2000 | 91.0 | 適應於碳素鋼、鑄鋼、高錳鋼、高強度鋼及合金鋼的粗車、銑削和刨削。 |

| YS2T | K30 M30 |

14.4-14.6 | 2200 | 91.5 | 屬超細顆粒合金,適於低速粗車,銑削耐熱合金及鈦合金,作切斷刀及絲錐、鋸片銑刀尤佳。 |

| YW1 | M10 | 12.6-13.5 | 1200 | 91.5 | 適於耐熱、高錳鋼、不銹鋼等難加工鋼材及普通鋼材和鑄鐵的加工。 |

| YW2 | M20 | 12.4-13.5 | 1350 | 90.5 | 適於耐熱鋼、高錳鋼、不銹鋼及高級合金鋼等特殊難加工鋼材的精加工,並精加工。普通鋼材和鑄鐵的加工。 |

| YW3 | M10 M20 |

12.7-13.3 | 1300 | 92 | 適於合金鋼、高強度鋼、低合金、超強度鋼的精加工和半精加工。亦可在衝擊力小的情況下精加工。 |

| YG6A | K10 | 14.6-15.0 | 1400 | 91.5 | 適於硬鑄鐵,有色金屬及其合金的半精加工,亦適於高錳鋼、淬火鋼、合金鋼的半精加工及精加工。 |

| YG6X | K10 | 14.6-15.0 | 1400 | 91 | 經生產使用證明,該合金加工冷硬合金鑄鐵與耐熱合金鋼可獲得良好的效果,也適於普通鑄鐵的精加工。 |

| YG6 | K20 | 14.6-15.0 | 1450 | 89.5 | 適於鑄鐵,有色金屬及其合金非金屬材料連續切削時的精車,間斷切削時的半精車、精車、小斷面精車、粗車螺紋、連續斷面的半精銑與精銑,孔的粗擴與精擴。 |

| YG8 | K30 | 14.5-14.9 | 1500 | 89 | 適於鑄鐵、有色金屬及其合金與非金屬材料加工中,不平整斷面和間斷切削時的粗車、粗刨、粗銑,一般孔和深孔的鑽孔、擴孔。 |

| YK15 | K15 K20 |

14.2-14.6 | 2100 | 91 | 適於加工整體合金鑽、銑、鉸等刀具。具有較高的耐磨性及韌性。 |

| YG15 | 13.9-14.2 | 2100 | 87 | 適於高壓縮率下鋼棒和鋼管拉伸,在較大應力下工作的頂鍛、穿孔及衝壓工具。 | |

| YG20 | 13.4-13.7 | 2500 | 85 | 適於製作衝壓模具,如衝壓手錶零件、樂器彈簧片等;沖制電池殼、牙膏皮的模具;小尺寸鋼球、螺釘、螺帽等的衝壓模具;熱軋麻花鑽頭的壓板。 | |

| YG20C | 13.4-13.7 | 2200 | 82 | 適於製作標準件、軸承、工具等行業用的冷鐓、冷沖、冷壓模具;彈頭對彈殼的衝壓模具。 | |

| YL10.1 | K12-K25 M10-M30 |

14.9 | 1900 | 91.5 | 具有較好的耐磨性和抗彎度,主要用為生產擠壓棒材,適合做一般鑽頭、刀具等耐磨件。 |

| YL10.2 | K25-K35 M25-M40 |

14.5 | 2200 | 91.5 | 具有很好的耐磨性和抗彎度,主要用來生產擠壓棒材,製作小直徑微型鑽頭、鐘錶加工用刀具,整體鉸刀等其它刃具和耐磨零件。 |

- Jan 14 Mon 2013 10:14

Tool coating - The super-hard thin film coating material

The super-hard thin film coating:

Depositing TiC, TiN, TiCN, Al2O3 ... hard ceramic coating with a few μm on carbide tool is more suitable for high speed machining than WC series, and with higher feed strength than ceramic. There are two depositing ways -- CVD (chemical vapor) and PVD method (physical vapor method).

Depositing methods:

|

Demand characteristics of the coating film:

- Hardness

- Wear

- Anti-melting

- Oxidation resistance

- Corrosion resistance

- Toughness

- The fatigue strength

- Thermal fatigue resistance

- Resistance to stripping

Application of cutter coating film characteristics:

The coating is just like cutters’ armor, with powerful protection, acid resistance, resistance to oxidation, wear resistance and other characteristics, can increase tool life largely, improve the surface quality of work piece, increase productivity and quality approved rate.

Coating treatment must be in proper arrangement in order to play a high-performance under the conditions of usage. Hence, we must understand the coating characteristics, and then applied to the cutting tool to achieve better results.

|

- Jan 09 Wed 2013 09:34

蒙耐爾合金(Monel)

蒙耐爾合金又稱鎳合金,是一種特殊的合金,金屬鎳為基體添加銅、鐵、錳等其它元素而成的合金。蒙耐爾具有高強度、高耐蝕、耐磨損的優良的物理特性,呈銀白色,在各種酸、堿介質中,具有使用壽命長的優點,因而廣泛應用於石油化工、核工業、國防工業等尖端工業上,做為重要的零部件和其它高強度、高耐蝕、高耐磨特性的複雜環境條件下使用的行業。

蒙耐爾合金在多種介質中均有良好的耐蝕性,它在空氣、土壤、淡水和海水中都很穩定。在土壤中的腐蝕速度不大於0.0003mm/a;在海水中的腐蝕速度為 0.03mm/a。蒙乃爾合金在非氧化性酸(硫酸、鹽酸、磷酸、氫氟酸)、鹽溶液和有機酸中,也有較好的耐蝕性。但在通氣介質或有氧化劑存在時,耐蝕性顯 著下降。在室溫下,在80%以下濃度的硫酸和20%濃度的鹽酸中,其腐蝕速度小於0.5mm/a。在中等濃度的磷酸和氫氟酸中,直至沸點溫度仍能保持穩 定,僅次於鉑和銀。但對應力腐蝕敏感,使用前應進行消除應力處理。

Monel合金是Ni-Cu系耐蝕合金,有兩種類型:加工強化型,有Monel400、404、R405等牌號;沉澱硬化型,有Monel K-500、502等牌號,常用Monel 400和K-500、Monel K-500的力學性能優於Monel 400,但耐蝕性稍差。

資料來源:網路彙整

- Dec 09 Sun 2012 09:36

切削液介紹-切削液的特性及選用

- Nov 28 Wed 2012 08:27

切削液介紹-切削液的分類

在金屬切削加工過程中,使用切削液是為了降低切削時的切削力,及時帶走切削區內產生的熱量以降低切削溫度,提高刀具耐用度,從而提高生產效率,改善工件表面粗糙度,保證工件加工精度,達到最佳的經濟效果。

切削液的分類:

- 非水溶性切削液

主要是切削油。有各種礦物油,如機械油、輕柴油、煤油等;還有動、 植物油,如豆油、豬油等;以及加入油性、極壓添加劑配製的混合油。它主要起潤滑作用。 - 水溶性切削液

主要成分為水,並加入防銹劑,也可加入適量的表面活性劑和油性添加劑,使其具有一定的潤滑性能。 - 乳化液

由礦物油、乳化劑及其它添加劑配製的乳化油加95%~98%的水稀釋而成的乳白色切削液,有良好的冷卻性能和清洗作用。

切削液具有的功能性分類:

- 冷卻性能:

切削液通過它從它所能達到最靠近熱源的刀具、切屑和工件表面上帶走大量的切削熱,從而降低切削溫度,提高刀具耐用度, 並減小工件與刀具的熱膨脹, 提高加工精度。切削液要有較高的熱導率和比熱容,較高的汽化熱。一定的流量和流速。水的冷卻性能最好,油類最差,乳化液介於兩者之間。 - 潤滑性能:

金屬切削時,切屑、工件與刀具之間的摩擦可分為:乾摩擦、流體潤滑摩擦和邊界潤滑摩擦。切削液滲入到切屑、刀具、工件的接觸面間,粘附在金屬表面上形成潤滑膜,減小它們之間的摩擦係數、減輕粘結現象、 抑制積屑瘤,並改善已加工表面的粗糙度,提高刀具耐用度。潤滑性能取決於切削液的滲透性、吸附薄膜形成能力與強度等。水溶性潤滑劑(聚乙烯醇、甘油)。 - 清洗性能:

沖走切削中產生的細屑、砂輪脫落下來的微粒等,起到清洗作用, 防止加工表面、機床導軌面受損; 有利於精加工、深孔加工、自動線加工中的排屑。在切削液中採用非離子性表面活性劑(如平平加、太古油)和陰離子表面活性劑(烷基苯磺酸鈉、十二烷基硫酸鈉)進行複配,能起到顯著降低切削液表面張力的作用,達到清洗的目的。 - 防銹性能:

加入防銹添加劑的切削液,還能在金屬表面上形成保護膜,使機床、工件、刀具免受周圍介質的腐蝕。 切削液的使用效果決定於切削液的類型、形態、用量、使用方法等。水溶性防銹劑品種較多,通常分為有機防銹劑與無機防銹劑兩類。現在一般採用鉬酸鈉(0.05%)替代亞硝酸鈉,以減少污染;和有機防銹劑(硼胺)複合使用,達到很好的防銹效果。 - 還具有防腐蝕性、抗菌性、防垢性、抗泡性、熱穩定性、無毒、無害、無刺激性氣味、不污染環境使用方便等作用。

資料來源:網路彙整

- Nov 25 Sun 2012 10:10

Anticlockwise milling and clockwise milling

Milling is one of the most common and most widely used processing methods, and for roughing milling of the various structural components and fine milling is almost by end milling. There are two ways, clockwise and anticlockwise milling, according to the cutting direction. The movement of the cutting edge and work piece is in the opposite direction or same direction, divided into the two kinds of conventional milling and climb milling.

Anticlockwise Milling:

Milling direction and feed in the opposite direction (milling against the feed) is anticlockwise milling; chip caused from the bottom into upper, so we also call it as up milling; Since the traditional processing and milling mostly used this way, so we also called it as conventional milling.

Characteristics of anticlockwise milling:

- Chip shape is from thin to thick, and cutter afford force from light into heavy, which may prevent the cutter fracture by the impact.

- Suitable for milling casting black surface.

- Can be used in the old milling machine, no screw invalid gap movement.

- More friction, the blade is easy to blunt, short life.

- Easy shaken, the machined surface is rough, poor machining accuracy.

- The device is not easy to settle, which is not suitable for milling thin parts.

- More energy consumption.

Clockwise milling:

The milling and feed in the same direction (milling with the feeds) called clockwise milling; Due to cutting action is from no-machining face of work piece into down place (chips from thick into thin), so it is called down milling or climb milling.

Characteristics of climb milling:

- Chip is from thick into thin, cutter affords force from heavy into light, easy to cause fracture by impact.

- Not suitable for milling castings, forgings, and the surface of the work piece with fish scale shape.

- The milling machine shall have a gap eliminator, or easy to produce screw invalid gap movement.

- Processing less friction, longer life of the cutter edge.

- Easy chucking, no vibration, and high accuracy of the machined surface.

- The device is easy to settle, it’s suitable for milling long thin work pieces.

- Less feed consumption.

In most of the milling case, in addition to the casting of the first milling and old milling Lo-gap chopping device need to use the anticlockwise milling, down milling is better than conventional milling.

- Oct 30 Tue 2012 11:30

Characteristics of Tungsten Carbide Cutter

There are two grades of cemented carbide, tungsten carbide and tungsten steel.

One is pure carbide and anti hole types. Pure carbide contains carbides and cobalt only, with best strength and anti-wear characteristics, and its strength and abrasion resistance will be reduced by adding any other substances, it is usually used for cutting cast iron and non-ferrous metal materials. But the pure carbide cannot endure high temperature, its scrap will stick on the cutter blade face easily during high heat, which causes the flank depression by its diffusion. Carbide added tantalum carbide and titanium carbide is with high temperature resistance because these two ingredients are with higher melting point than tungsten carbide, relatively its strength and anti-ear characteristics are lower than pure carbide.

tungsten steel material properties:

| ISO classification |

Grade | Usage | Rockwell Hardness | Bending Force | Ingredients | ||||

| HRA | (kg/mm2) | W | Co | Ti | Ta | C | |||

| P | P01 | toughness↓big big↑wear |

91.5↑ | 70↑ | 30-78 | 4-8 | 10-40 | 0-25 | 7-3 |

| P10 | 91↑ | 90↑ | 50-80 | 4-9 | 8-20 | 0-20 | 7-10 | ||

| P20 | 90↑ | 110↑ | 60-83 | 5-10 | 5-15 | 0-15 | 6-9 | ||

| P30 | 89↑ | 130↑ | 70-84 | 6-12 | 3-12 | 0-12 | 6-8 | ||

| P40 | 88↑ | 150↑ | 65-85 | 7-15 | 2-10 | 0-10 | 6-8 | ||

| P50 | 87↑ | 170↑ | 60-83 | 9-20 | 2-8 | 0-8 | 5-7 | ||

| M | M10 | toughness↓big big↑wear |

91↑ | 100↑ | 70-86 | 4-9 | 3-11 | 0-11 | 6-8 |

| M20 | 90↑ | 110↑ | 70-86 | 5-11 | 2-10 | 0-10 | 5-8 | ||

| M30 | 89↑ | 130↑ | 70-86 | 6-13 | 2-9 | 0-9 | 5-8 | ||

| M40 | 87↑ | 160↑ | 65-85 | 8-20 | 1-7 | 0-7 | 5-7 | ||

| K | K01 | toughness↓big big↑wear |

91.5↑ | 100↑ | 83-91 | 3-6 | 0-2 | 0-3 | 5-7 |

| K10 | 90.5↑ | 120↑ | 84-90 | 4-7 | 0-1 | 0-2 | 5-6 | ||

| K20 | 89↑ | 140↑ | 83-89 | 5-8 | 0-1 | 0-2 | 5-6 | ||

| K30 | 88↑ | 150↑ | 81-88 | 6-11 | 0-1 | 0-2 | 5-6 | ||

| K40 | 87↑ | 160↑ | 79-87 | 7-16 | -- | -- | 5-6 | ||

tungsten steel tool suitability:

| ISO classification |

Grade | Work Material | Cutting Type | Working Conditions |

| P | P01 | cast steel, steel | Precise turning, precise boring | Apply to cutting high-speed steel and small feed, or require the dimensional accuracy and good surface of the work piece, and work under no vibration state of processing. |

| P10 | cast steel, steel | turning, by die cutting, thread cutting | High ~ middle speed cutting, Small ~ middle milling area, middle feed or under good processing | |

| P20 | cast steel, steel、malleable iron (Long chip) | Turning, by the die cutting, milling, planning cutting | Middle speed cutting, middle feed power, the most popular one among P series. Planning feed should be small, with good machining conditions. | |

| P30 | cast steel, steel、malleable iron (Long chip) | turning, milling, planning | Low ~ medium-speed cutting, medium ~ high amount of feed, or the surface hardness of work piece with uneven hardness, changes of feeding, and vibration conditions . | |

| P40 | Steel, cast iron with sand hole | turning, planning | low-speed cutting, large amount of feed, and under the worst processing conditions | |

| P50 | low to middle tensile strength steel | turning, planning | low-speed cutting, large amount of feed, and under the worst processing conditions | |

| cast iron with sand hole | turning, planning | low-speed cutting, large amount of feed, and under worse processing conditions than P40 | ||

| M | M10 | steel, cast steel, cast iron | turning | medium to high-speed cutting, small to medium amount of feed, or under the better processing conditions, for cutting steel and cast iron materials. |

| High manganese steel, Eos Tiantie Gang, special cast iron | turning | Medium to high-speed cutting, small to medium amount of feed, or under the better conditions. | ||

| M20 | steel, cast steel, cast iron | turning, planning | Middle speed milling, medium feed, or under bad processing conditions, for cutting steel and cast iron materials. | |

| Eos Tiantie Gang, special cast iron, high manganese steel | turning, planning | Medium speed milling, middle feed,, or cut under a good processing conditions. | ||

| M30 | steel, cast steel, cast iron, Oswald Tiantie Gang, special cast iron, heat-resistant steel | turning, milling, breaking | Medium speed milling, middle to large amount of feed, or thick rough material and material with sand holes, welding materials, under worse processing conditions than M20. | |

| M40 | cutting steel, non-ferrous metal | turning, breaking | High speed cutting, middle to large amount of feed, complex shape of the cutting edge, it’s the M Series most needed toughness cutting processing conditions. | |

| K | K01 | cast iron | precision turning, precision honing, fine milling | High speed cutting, small amount of feed, under good cutting conditions without vibration. |

| K10 | chilled cast iron, hard cast iron, hardened steel | turning | very low speed cutting, small amount of feed, under good cutting conditions without vibration. | |

| High silicon aluminum alloy, ceramics, asbestos, cardboard, graphite, | Cutting under good cutting conditions without vibration. | |||

| cast iron above HB200, malleable iron (long cutting) | turning, milling, honing cutting, broaching, reaming |

Middle speed cutting, small amount of feed, widely used for K series, or under vibration-free machining conditions. |

||

| chilled steel | turning | low-speed cutting, small amount of feed or under cutting conditions of smaller vibration. | ||

| silicon-aluminum alloy, hard copper alloy, hard rubber, glass, porcelain, plastics | under cutting conditions of smaller vibration. | |||

| K20 | Cast iron belowHB220 | turning, milling, planning, reaming, drilling | Middle speed cutting, medium to large amount of feed, used for general machining or request of the powerful the wayward processing conditions | |

| Non ferrous metal materials | Request under powerful the wayward processing conditions | |||

| K30 | low tensile strength steel, low hardness cast iron | turning, milling, planning | low speed cutting, small amount of feed, under better processing conditions. | |

| K40 | non-ferrous metal of low hardness materials, wood | turning, milling, planning | cutting under the conditions worse than K30 |

Reference Information Source: tool designed Huang Rongwen

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool, saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter production and machinery industry.

- Oct 27 Sat 2012 09:40

不銹鋼加工

由於不銹鋼所具有耐蝕能力,並在較高溫度(>450℃)下具有較高的強度特性,越來越廣泛地應用於航空、航太、化工、石油、建築和食品等工業部門及日常生活中。所含的合金元素對切削加工性影響很大,有的甚至很難切削。

- 加工硬化嚴重

- 切削力大

- 切削溫度高

- 切屑不易折斷、易粘結

- 刀具易磨損

- 線膨脹係數大

不銹鋼加工原則:

- 選用合理的刀具材料

- 改善切削條件

- 選擇合理的切削用量

- 合理設計刀具結構及刀具幾何參數

- 選用適當的切削液和供液方法

各加工方式加工應對:

| 鑽孔加工 | 鉸孔加工 | 鏜孔加工 | |

| 工件材質 | 不銹鋼 | ||

| 刀具幾何參數設計 | 切削力及切削溫度均集中在鑽尖上,為提高鑽頭切削部位的耐用度,頂角一般選135°~140°,鑽頭的橫刃變寬,造成切削阻力增大,因而必須對鑽頭橫刃進行修磨,修磨後橫刃的斜角為47°~55°,橫刃前角為3°~5°,修磨橫刃時,應將切削刃與圓柱面轉角處修磨成圓角,以增加橫刃強度,後角應以12°~15°為宜,需要在鑽頭兩個後刀面上開交錯分佈的分屑槽。 | 為增強刀齒強度並防止鉸削時產生切屑堵塞現象,鉸刀齒數一般比較少。鉸刀前角一般為8°~12°,但在某些特定情況,為了實現高速鉸削,也可採用0°~5°前角;後角一般為8°~12°;主偏角的選擇視孔的不同而異,一般情況下通孔為15°~30°,不通孔為45°;鉸孔時為了使切屑向前排出,也可適當增加刃傾角角度,刃傾角角度一般為10°~20°;刃帶寬度為0.1~0.15mm;鉸刀上倒錐應較普通鉸刀大,硬質合金鉸刀一般為0.25~0.5mm/100mm,高速鋼鉸刀為0.1~0.25mm/100mm | 為使切削輕快、順利,硬質合金刀具宜採用較大的前角,以提高刀具壽命。一般粗加工時,前角取10°~20°,半精加工時取15°~20°;精加工時取20°~30°。主偏角的選擇依據是,當工藝系統剛性良好時,可取30°~45°;剛性差時,則取60~75°,當工件長度與直徑之比超過10倍時,可取90°。陶瓷刀具均採用負前角進行切削。前角大小一般選應-5°~-12°。這樣有利於加強刀刃,充分發揮陶瓷刀具抗壓強度較高的優越性。後角大小直接影響刀具磨損,對刀刃強度也有影響,一般選用5°~12°。主偏角的改變會影響徑向切削分力與軸向切削分力的變化以及切削寬度和切削厚度的大小。因為工藝系統的振動對陶瓷刀具極為不利,所以主偏角的選擇要有利於減少這種振動,一般選取30°~75°。選用CBN作為刀具材料時,刀具幾何參數為前角0°~10°,後角12°~20°,主偏角45°~90°。前刀面刃磨時粗糙度值要小,刀具刃口應保持鋒利,以減少加工硬化,注意斷屑槽的磨削。 |

| 刀具材料選擇 | 採用硬質合金刀具,可採用金屬陶瓷材料刀具 | 粗鉸時應採用硬質合金刀具,精鉸時可採用高速鋼刀具,可採用金屬陶瓷材料刀具 | 刀具材料應儘量選擇強度高、導熱性好的YW或YG類硬質合金。精加工時也可使用YT14及YT15硬質合金刀片。批量加工上述材料零件時,可採用金屬陶瓷材刀具,及採用CBN(立方氮化硼)刀片, |

| 切削用量選擇 | 切削用量的選擇應從降低切削溫度的基本點出發,一般情況下,切削速度以12~15m/min較為合適。進給量選擇太小將會使刀具在硬化層內切削,加劇磨損;而進給量如果太大,又會使表面粗糙度變差。綜合上述兩個因素,進給量選擇為0.32~0.50mm/r為宜。 | 進給量為0.08~0.4mm/r,切削速度為10~20m/min,粗鉸餘量一般為0.2~0.3mm,精鉸餘量為0.1~0.2mm。 | 加工時宜選用低速和較大進給量進行切削。由於陶瓷刀具有優越的耐熱性和耐磨性,切削用量對刀具磨損壽命的影響比硬質合金刀具要小。一般情況下,用陶瓷刀具加工時,進給量對刀具的破損影響最為敏感,盡可能選擇高的切削速度、較大的背吃刀量和比較小的進給量。 |

| 切削液選擇 | 可採用乳化液作為冷卻介質 | 可採用全損耗系統用油或二硫化鉬作為冷卻介質 | 在鏜削中選用抗粘結和散熱性好的切削液相當重要,如選用含氯較高的切削液,以及具有良好冷卻、清洗、防銹和潤滑作用的不含礦物油、不含亞酸鹽的水溶液,如H1L-2合成切削液。 |

資料來源:網路彙整

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

- Oct 07 Sun 2012 11:17

不銹鋼標準鋼號對照表

不銹鋼通俗地說,不銹鋼就是不容易生銹的鋼,實際上一部分不銹鋼,既有不鏽性,又有耐酸性(耐蝕性)。不鏽鋼的不鏽性和耐蝕性是由於其表面上富鉻氧化膜(鈍化膜)的形成。由於不銹鋼材具有優異的耐蝕性、成型 性、相容性以及在很寬溫度範圍內的強韌性等系列特點,所以在重工業、輕工業、生活用品行業以及建築裝 飾等行業中獲取得廣泛的應用。上一篇”不鏽鋼介紹”有更詳細介紹,此篇介紹各種不銹鋼標準鋼號對照表。

不銹鋼標準鋼號對照表:

| 中國 GB1220-92[84] GB3220-92[84] |

日本 JIS |

美國 AISI UNS |

英國 BS 970 Part4 BS 1449 Part2 |

德國 DIN 17440 DIN 17224 |

| 1Cr17Mn6Ni5N | SUS201 | 201 | -- | -- |

| 1Cr18Mn8Ni5N | SUS202 | 202 | -- | -- |

| -- | -- | S20200 | 284S16 | -- |

| 2Cr13Mn9Ni4 | -- | -- | -- | -- |

| 1Cr17Ni7 | SUS301 | 301 | -- | -- |

| -- | -- | S30100 | 301S21 | X12CrNi177 |

| 1Cr17Ni8 | SUS301J1 | -- | -- | X12CrNi177 |

| 1Cr18Ni9 | SUS302 | 302 | 302S25 | X12CrNi188 |

| 1Cr18Ni9Si3 | SUS302B | 302B | -- | -- |

| Y1Cr18Ni9 | SUS303 | 303 | 303S21 | X12CrNiS188 |

| Y1Cr18Ni9Se | SUS303Se | 303Se | 303S41 | -- |

| 0Cr18Ni9 | SUS304 | 304 | 304S15 | X2CrNi89 |

| 00Cr19Ni10 | SUS304L | 304L | 304S12 | X2CrNi189 |

| 0Cr19Ni9N | SUS304N1 | 304N | -- | -- |

| 00Cr19Ni10NbN | SUS304N | XM21 | -- | -- |

| 00Cr18Ni10N | SUS304LN | -- | -- | X2CrNiN1810 |

| 1Cr18Ni12 | SUS305 | S30500 | 305S19 | X5CrNi1911 |

| [0Cr20Ni10] | SUS308 | 308 | -- | -- |

| 0Cr23Ni13 | SUS309S | 309S | -- | -- |

| 0Cr25Ni20 | SUS310S | 310S | -- | -- |

| 0Cr17Ni12Mo2N | SUS315N | 316N,S31651 | -- | -- |

| 0Cr17Ni12Mo2 | SUS316 | 316 | 316S16 | X5CrNiMo1812 |

| 00Cr17Ni14Mo2 | SUS316L | 316L | 316S12 | X2CrNiMo1812 |

| 0Cr17Ni12Mo2N | SUS316N | 316N | -- | -- |

| 00Cr17Ni13Mo2N | SUS316LN | -- | -- | X2CrNiMoN1812 |

| 0Cr18Ni12Mo2Ti | -- | -- | 320S17 | X10CrNiMo1810 |

| 0Cr18Ni14Mo2Cu2 | SUS316J1 | -- | -- | -- |

| 00Cr18Ni14Mo2Cu2 | SUS316J1L | -- | -- | -- |

| 0Cr18Ni12Mo3Ti | -- | -- | -- | -- |

| 1Cr18Ni12Mo3Ti | -- | -- | -- | -- |

| 0Cr19Ni13Mo3 | SUS317 | 317 | 317S16 | -- |

| 00Cr19Ni13Mo3 | SUS317L | 317L | 317S12 | X2CrNiMo1816 |

| 0Cr18Ni16Mo5 | SUS317J1 | -- | -- | -- |

| 0Cr18Ni11Ti | SUS321 | 321 | -- | X10CrNiTi189 |

| 1Cr18Ni9Ti | -- | -- | -- | -- |

| 0Cr18Ni11Nb | SUS347 | 347 | 347S17 | X10CrNiNb189 |

| 0Cr18Ni13Si4 | SUSXM15J1 | XM15 | -- | -- |

| 0Cr18Ni9Cu3 | SUSXM7 | XM7 | -- | -- |

| 1Cr18Mn10NiMo3N | -- | -- | -- | -- |

| 1Cr18Ni12Mo2Ti | -- | -- | 320S17 | X10CrNiMoTi1810 |

| 00Cr18Ni5Mo3Si2 | -- | S31500 | -- | 3RE60(瑞典) |

| 0Cr26Ni5Mo2 | SUS329J1 | -- | -- | -- |

| 1Cr18Ni11Si4AlTi | -- | -- | -- | -- |

| 1Cr21Ni5Ti | -- | -- | -- | -- |

| 0Cr13 | SUS410S | S41000 | -- | X7Cr13 |

| 1Cr13 | SUS410 | 410 | 410S21 | X10Cr13 |

| 2Cr13 | SUS420J1 | 420 | 420S29 | X20Cr13 |

| -- | -- | S4200 | 420S27 | -- |

| 3Cr13 | SUS420J2 | -- | 420S45 | -- |

| 3Cr13Mo | -- | -- | -- | -- |

| 3Cr16 | SUS429J1 | -- | -- | -- |

| 1Cr17Ni2 | SUS431 | 431 | 431S29 | X22CrNi17 |

| 7Cr17 | SUS440A | 440A | -- | -- |

| 11Cr17 | SUS440C | 440C | -- | -- |

| 8Cr17 | SUS440B | 44013 | -- | -- |

| 1Cr12 | -- | -- | -- | -- |

| 4Cr13 | SUS420J2 | -- | -- | X4DCr13 |

| 9Cr18 | SUS440C | 440C | -- | X105CrMo17 |

| 9Cr18Mo | SUS440C | 440C | -- | -- |

| 9Cr18MoV | SUS440B | 440B | -- | X90CrMoV18 |

| 0Cr17Ni4Cu4Nb | SUS630 | 630 | -- | -- |

| 0Cr17Ni7Al | SUS631 | 631 | -- | -- |

| -- | -- | S17700 | -- | X7CrNiAl177 |

| 0Cr15Ni7Mo2Al | -- | 632 | -- | -- |

| -- | -- | S15700 | -- | -- |

| 00Cr12 | SUS410 | -- | -- | -- |

| 0Cr13Al[00Cr13Al] | SUS405 | 405 | -- | -- |

| -- | -- | S40500 | 405S17 | X7CrAl13 |

| 1Cr15 | SUS429 | 429 | -- | -- |

| 1Cr17 | SUS430 | 430 | -- | -- |

| -- | -- | S43000 | 430S15 | X8Cr17 |

| [Y1Cr17] | SUS430F | 430F | -- | -- |

| -- | -- | S43020 | -- | X12CrMoS17 |

| 00Cr17 | SUS430LX | -- | -- | -- |

| 1Cr17Mo | SUS434 | 434 | -- | -- |

| -- | -- | S43400 | 434S19 | X6CrMo17 |

| 00Cr17Mo | SUS436L | -- | -- | -- |

| 00Cr18Mo2 | SUS444 | -- | -- | -- |

| 00Cr27Mo | SUSXM27 | XM27 | -- | -- |

| -- | -- | S44625 | -- | -- |

| 00Cr30Mo2 | SUS447J1 | -- | -- | -- |

| 1Cr12 | SUS403 | 403,S40300 | 403S17 | -- |

| 1Cr13Mo | SUS410J1 | -- | -- | -- |

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

- Oct 06 Sat 2012 10:12

不鏽鋼介紹

不鏽鋼(Inox)不像普通鋼那樣容易腐蝕生鏽。鉻是使不銹鋼獲得耐蝕性 的基本元素,鋼中加入鉻、鎳使其表面會產生防鏽的氧化膜,從而保護鋼材本身受到外界環境中的空氣(尤指氧氣 )、水、某些酸、鹼的氧化腐蝕,為了保持不銹鋼所固有的耐腐蝕性,鋼必須含有 12%以上的鉻,除鉻外,常用的合金元素還有鎳、鉬、鈦、鈮、銅、氮等,以滿足各種用途對不銹鋼組織 和性能的要求。

- Jul 13 Fri 2012 08:53

HSS材質對照表

HSS材質對照表

此表以HSS材料為主,將常用的材料規格號碼、記號加以歸納、整理、分析及化學成分及機械性質的分析。

| 台灣 | 中國 | 日本 | 美國 | 德國 | |

| CNS | GB | JIS | ASTM | DIN | |

| 2904 | 9943 | G4403 | A600 | 17350 | |

| 材料號碼 | 記號 | ||||

| SKH2 | W18Cr4V | SKH2 | T1 | 1.3355 | S 18-0-1 |

| SKH3 | W18Cr4V5Co5 | SKH3 | T4 | 1.3255 | S 18-1-2-5 |

| SKH4 | W18Cr4V5Co8 | SKH4 | T5 | 1.3265 | S 18-1-2-10 |

| SKH10 | W12Cr4V5Co5 | SKH10 | T15 | 1.3202 | S 12-1-4-5 |

| SKH51 | W6Mo5Cr4V2 | SKH51 | M2 | 1.3342 | S 6-5-2 |

| SKH52 | W6Mo5Cr4V3 | SKH52 | M3-1 | 1.3344 | S 6-5-3 |

| SKH53 | -- | SKH53 | M3-2 | 1.3344 | S 6-5-3 |

| SKH54 | -- | SKH54 | M4 | 1.3344 | S 6-5-3 |

| SKH55 | W6Mo5Cr4V2Co5 | SKH55 | -- | 1.3243 | S 6-5-2-5 |

| SKH56 | W6Mo5Cr4V2Co5 | SKH56 | M36 | -- | -- |

| SKH57 | -- | SKH57 | M41 | 1.3207 | S 10-4-3-10 |

| SKH58 | -- | SKH58 | M7 | -- | -- |

| SKH59 | W2Mo9Cr4VCo8 | SKH59 | M42 | 1.3247 | S 2-10-1-8 |

以下為各種材質的化學成份及機械性質性:

- SKH2材質化學成分及機械性質表

- SKH3材質化學成分及機械性質表

- SKH4材質化學成分及機械性質表

- SKH10材質化學成分及機械性質表

- SKH51材質化學成分及機械性質表

- SKH52材質化學成分及機械性質表

- SKH53材質化學成分及機械性質表

- SKH54材質化學成分及機械性質表

- SKH55材質化學成分及機械性質表

- SKH56材質化學成分及機械性質表

- SKH57材質化學成分及機械性質表

- SKH58材質化學成分及機械性質表

- SKH59材質化學成分及機械性質表

SKH2材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | DIN | |

| 記號 | SKH2 | W18Cr4V | SKH2 | T1 | S 18-0-1 | |

| 化學成分(%) Chemical composition |

C | 0.73-0.83 | 0.7-0.8 | 0.73-0.83 | 0.65-0.80 | 0.70-0.78 |

| Si | ≦0.4 | 0.2-0.4 | ≦0.4 | 0.2-0.4 | ≦0.45 | |

| Mn | ≦0.4 | 0.1-0.4 | ≦0.4 | 0.1-0.4 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | ≦0.3 | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.8-4.4 | 3.8-4.5 | 3.75-4.50 | 3.8-4.4 | |

| Mo | -- | ≦0.3 | -- | -- | -- | |

| W | 17-18.7 | 17.5-19.0 | 17-18.7 | 17.25-18.75 | 17.5-18.5 | |

| V | 1.0-1.2 | 1.0-1.4 | 1.0-1.2 | 0.9-1.3 | 1.0-1.2 | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦269 | ≦255 | ≦269 | ≦255 | 240-300 |

| 焠火HRC | ≧63 | ≧63 | ≧63 | ≧63 | ≧64 | |

SKH3材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | DIN | |

| 記號 | SKH3 | W18Cr4V5Co5 | SKH3 | T4 | S 18-1-2-5 | |

| 化學成分(%) Chemical composition |

C | 0.73-0.83 | 0.7-0.8 | 0.73-0.83 | 0.7-0.8 | 0.75-0.83 |

| Si | ≦0.4 | 0.2-0.4 | ≦0.4 | 0.2-0.4 | ≦0.45 | |

| Mn | ≦0.4 | 0.1-0.4 | ≦0.4 | 0.1-0.4 | ≦0.04 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | -- | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | |

| Mo | -- | 0.4-1.0 | -- | 0.4-1.0 | 0.5-0.8 | |

| W | 17-19.0 | 17.5-19.0 | 17-19 | 17. 5-19 | 17-18.5 | |

| V | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 1.4-1.7 | |

| Co | -- | 4.25-5.75 | 4.5-5.5 | 4.25-5.75 | 4.5-5.5 | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦269 | -- | ≦269 | ≦269 | 240-300 |

| 焠火HRC | ≧64 | -- | ≧63 | ≧63 | ≧64 | |

SKH4材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | DIN | |

| 記號 | SKH4 | W18Cr4V2Co8 | SKH4 | T5 | S 18-1-2-10 | |

| 化學成分(%) Chemical composition |

C | 0.73-0.83 | 0.75-0.85 | 0.73-0.83 | 0.75-0.85 | 0.72-0.80 |

| Si | ≦0.4 | 0.2-0.4 | ≦0.4 | 0.2-0.4 | ≦0.45 | |

| Mn | ≦0.4 | 0.2-0.4 | ≦0.4 | 0.2-0.4 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | -- | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.75-5.00 | 3.8-4.5 | 3.75-5.00 | 3.8-4.5 | |

| Mo | -- | 0.50-1.25 | -- | 0.5-1.25 | 0.5-4.5 | |

| W | 17-19.0 | 17.5-19 | 17.5-19.0 | 17.5-19 | 17.5-18.5 | |

| V | 1.0-1.5 | 1.8-2.4 | 1.0-1.5 | 1.8-2.4 | 1.4-1.7 | |

| Co | 9.0-11.0 | 7.0-9.5 | 9.0-11.0 | 7.0-9.5 | 9.0-10.0 | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦285 | ≦285 | ≦285 | ≦285 | 240-300 |

| 焠火HRC | ≧64 | ≧63 | ≧64 | ≧63 | ≧64 | |

SKH10材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | DIN | |

| 記號 | SKH10 | W12Cr4V5Co5 | SKH10 | T15 | S 12-1-4-5 | |

| 化學成分(%) Chemical composition |

C | 1.45-1.6 | 1.5-1.6 | 1.45-1.6 | 1.5-1.6 | 1.30-1.45 |

| Si | ≦0.45 | ≦0.4 | ≦0.45 | 0.15-0.40 | ≦0.45 | |

| Mn | ≦0.4 | 0.15-0.4 | ≦0.4 | 0.15-0.40 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | -- | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.75-5.00 | 3.8-4.5 | 3.75-5.00 | 3.8-4.5 | |

| Mo | -- | ≦1.0 | -- | ≦1.0 | 0.7-1.0 | |

| W | 11.5-13.5 | 11.75-13.00 | 11.5-13.5 | 11.75-13.00 | 11.5-12.5 | |

| V | 4.2-5.2 | 4.5-5.25 | 4.2-5.2 | 4.5-5.25 | 3.5-4.0 | |

| Co | 4.2-5.2 | 4.75-5.25 | 4.2-5.2 | 4.75-5.25 | 4.5-5.0 | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦285 | ≦277 | ≦285 | ≦277 | 240-300 |

| 焠火HRC | ≧64 | ≧65 | ≧64 | ≧65 | ≧65 | |

SKH51材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | DIN | |

| 記號 | SKH51 | W6Mo5Cr4V2 | SKH51 | M2 | S 6-5-2 | |

| 化學成分(%) Chemical composition |

C | 0.8-0.9 | 0.8-0.9 | 0.8-0.9 | 078-0.88 | 0.86-0.94 |

| Si | ≦0.45 | 0.2-0.4 | ≦0.45 | 0.20-0.45 | ≦0.45 | |

| Mn | ≦0.4 | 0.15-0.4 | ≦0.4 | 0.15-0.40 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | -- | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.8-4.4 | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | |

| Mo | 4.7-5.2 | 4.5-5.5 | 4.5-5.5 | 4.75-5.50 | 4.7-5.2 | |

| W | 5.9-6.7 | 5.50-6.75 | 5.9-6.7 | 5.50-6.75 | 6.0-6.7 | |

| V | 1.7-2.1 | 1.75-2.20 | 1.6-2.1 | 1.75-2.20 | 1.7-2.0 | |

| Co | -- | -- | -- | -- | -- | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦262 | ≦255 | ≦262 | -- | 240-300 |

| 焠火HRC | ≧64 | ≧63 | ≧64 | -- | ≧64 | |

SKH52材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | DIN | |

| 記號 | SKH52 | W6Mo5Cr4V3 | SKH52 | M3-1 | S 6-5-3 | |

| 化學成分(%) Chemical composition |

C | 1.0-1.1 | 1.0-1.1 | 1.0-1.1 | 1.0-1.1 | 1.17-1.27 |

| Si | ≦0.45 | ≦0.45 | ≦0.45 | 0.20-0.45 | ≦0.45 | |

| Mn | ≦0.4 | 0.15-0.4 | ≦0.4 | 0.15-0.40 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | 0.20-0.45 | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | |

| Mo | 5.5-6.7 | 4.75-6.5 | 5.5-6.7 | 4.75-6.50 | 4.7-5.2 | |

| W | 5.5-6.7 | 5.00-6.75 | 5.5-6.7 | 5.50-6.75 | 6.0-6.7 | |

| V | 2.3-2.6 | 2.25-2.75 | 2.3-2.6 | 2.25-2.75 | 2.7-3.2 | |

| Co | -- | -- | -- | -- | -- | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦262 | ≦255 | ≦262 | ≦255 | 240-300 |

| 焠火HRC | ≧64 | ≧65 | ≧64 | ≧64 | ≧65 | |

SKH53材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | JIS | ASTM | DIN | |

| 記號 | SKH53 | SKH53 | M3-2 | S 6-5-3 | |

| 化學成分(%) Chemical composition |

C | 1.0-1.25 | 1.0-1.25 | 1.15-1.25 | 1.17-1.27 |

| Si | ≦0.45 | ≦0.45 | 0.20-0.45 | ≦0.45 | |

| Mn | ≦0.4 | ≦0.4 | 0.15-0.40 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | |

| Mo | 4.7-5.2 | 4.7-5.2 | 4.75-6.50 | 4.7-5.2 | |

| W | 5.5-6.5 | 5.5-6.5 | 5.00-6.75 | 6.0-6.7 | |

| V | 2.7-3.2 | 2.7-3.2 | 2.75-3.25 | 2.7-3.2 | |

| Co | -- | -- | -- | -- | |

| Cu | ≦0.25 | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦269 | ≦269 | ≦255 | 240-300 |

| 焠火HRC | ≧64 | ≧64 | ≧64 | ≧65 | |

SKH54材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | JIS | ASTM | DIN | |

| 記號 | SKH54 | SKH53 | M4 | S 6-5-3 | |

| 化學成分(%) Chemical composition |

C | 1.25-1.40 | 1.25-1.40 | 1.25-1.40 | 1.17-1.27 |

| Si | ≦0.45 | ≦0.45 | 0.20-0.45 | ≦0.45 | |

| Mn | ≦0.4 | ≦0.4 | 0.15-0.40 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.8-4.5 | 3.75-4.70 | 3.8-4.5 | |

| Mo | 4.2-5.0 | 4.2-5.0 | 4.25-5.50 | 4.7-5.2 | |

| W | 5.2-6.0 | 5.2-6.0 | 5.25-6.50 | 6.0-6.7 | |

| V | 3.7-4.2 | 3.7-4.2 | 3.75-4.50 | 2.7-3.2 | |

| Co | -- | -- | -- | -- | |

| Cu | ≦0.25 | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦269 | ≦269 | ≦255 | 240-300 |

| 焠火HRC | ≧64 | ≧64 | ≧64 | ≧65 | |

SKH55材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | DIN | |

| 記號 | SKH55 | W6Mo5Cr4V2Co5 | SKH55 | S 6-5-2-5 | |

| 化學成分(%) Chemical composition |

C | 0.85-0.95 | 0.8-0.9 | 0.8-0.9 | 0.88-0.96 |

| Si | ≦0.45 | 0.2-0.45 | ≦0.45 | ≦0.45 | |

| Mn | ≦0.4 | 0.15-0.4 | ≦0.4 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | -- | 0.20-0.45 | -- | -- | |

| Cr | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | 3.8-4.5 | |

| Mo | 4.7-5.2 | 4. 5-5.5 | 4.7-5.2 | 4.7-5.2 | |

| W | 5.9-6.7 | 5.5-6.5 | 5.9-6.7 | 6.0-6.7 | |

| V | 1.7-2.1 | 1.75-2.25 | 1.7-2.1 | 1.7-2.0 | |

| Co | 4.5-5.0 | 4.5-5.5 | 4.5-5.0 | 4.5-5.0 | |

| Cu | -- | -- | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦269 | ≦269 | ≦269 | 240-300 |

| 焠火HRC | ≧64 | ≧64 | ≧64 | ≧64 | |

SKH56材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | |

| 記號 | SKH56 | W6Mo5Cr4V2Co5 | SKH56 | M3-1 | |

| 化學成分(%) Chemical composition |

C | 0.85-0.96 | 0.8-0.9 | 0.85-0.96 | 0.8-0.9 |

| Si | ≦0.4 | 0.2-0.45 | ≦0.4 | 0.20-0.45 | |

| Mn | ≦0.4 | 0.15-0.40 | ≦0.4 | 0.15-0.45 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | -- | ≦0.25 | -- | |

| Cr | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | 3.75-4.0 0 | |

| Mo | 4.7-5.2 | 4.5-5.5 | 4.7-5.2 | 4.5-5.5 | |

| W | 5.9-6.7 | 5.5-6. 5 | 5.9-6.7 | 5.5-6. 5 | |

| V | 1.7-2.1 | 1.7-2.25 | 1.7-2.1 | 1.75-2.25 | |

| Co | 7.0-9.0 | 4.5-5.5 | 7.0-9.0 | 7.75-8.75 | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | |

| 機械性質 (硬度) |

退火HB | ≦285 | ≦269 | ≦285 | ≦269 |

| 焠火HRC | ≧64 | ≧64 | ≧64 | ≧64 | |

SKH57材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | JIS | ASTM | DIN | |

| 記號 | SKH57 | SKH57 | M41 | S 10-4-3-10 | |

| 化學成分(%) Chemical composition |

C | 1.20-1.35 | 1.20-1.35 | 1.05-1.15 | 1.20-1.35 |

| Si | ≦0.4 | ≦0.4 | 0.15-0.2 | ≦0.45 | |

| Mn | ≦0.4 | ≦0.4 | 0.2-0.60. | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | ≦0.25 | -- | -- | |

| Cr | 3.8-4.5 | 3.8-4.5 | 3.75-4.50 | 3.8-4.5 | |

| Mo | 3.2-3.9 | 3.2-3.9 | 3.25-4.25 | 3.2-3.9 | |

| W | 9.0-10.0 | 9.0-10.0 | 6.25-7.00 | 9.0-10.0 | |

| V | 3.0-3.5 | 3.0-3.5 | 1.75-2.25 | 3.0-3.5 | |

| Co | 9.5-10.5 | 9.5-10.5 | 4.75-5.75 | 9.5-10.5 | |

| Cu | ≦0.25 | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦293 | ≦293 | ≦269 | 240-300 |

| 焠火HRC | ≧66 | ≧66 | ≧66 | ≧66 | |

SKH58材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | JIS | ASTM | |

| 記號 | SKH58 | SKH58 | M7 | |

| 化學成分(%) Chemical composition |

C | 0.95-1.05 | 0.95-1.05 | 0.97-1.05 |

| Si | ≦0.7 | ≦0.7 | 0.2-0.55 | |

| Mn | ≦0.4 | ≦0.4 | 0.15-0.40 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | -- | -- | -- | |

| Cr | 3.5-4.5 | 3.5-4.5 | 3.75-4.50 | |

| Mo | 8.2-9.2 | 8.2-9.2 | 8.2-9.2 | |

| W | 1.5-2.1 | 1.5-2.1 | 1.4-2.1 | |

| V | 1.7-2.2 | 1.7-2.2 | 1.75-2.25 | |

| Co | -- | -- | -- | |

| Cu | ≦0.25 | ≦0.25 | -- | |

| 機械性質 (硬度) |

退火HB | ≦269 | ≦269 | ≦277 |

| 焠火HRC | ≧66 | ≧66 | ≧65 | |

SKH59材質化學成分及機械性質表。點擊回到列表

| 標準代碼 | CNS | GB | JIS | ASTM | DIN | |

| 記號 | SKH59 | W2Mo9Cr4VCo8 | SKH59 | M42 | S 6-5-3 | |

| 化學成分(%) Chemical composition |

C | 1.05-1.15 | 1.05-1.15 | 1.05-1.15 | 1.05-1.15 | 1.05-1.15 |

| Si | ≦0.7 | 0.15-0.65 | ≦0.7 | 0.15-0.65 | ≦0.45 | |

| Mn | ≦0.4 | 0.15-0.4 | ≦0.4 | 0.15-0.40 | ≦0.4 | |

| P | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| S | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | ≦0.03 | |

| Ni | ≦0.25 | -- | ≦0.25 | -- | -- | |

| Cr | 3.5-4.5 | 3.50-4.25 | 3.5-4.5 | 3.50-4.25 | 3.6-4.4 | |

| Mo | 9.0-10.0 | 9.0-10.0 | 9.0-10.0 | 9.0-10.0 | 9.0-10.0 | |

| W | 1.2-1.9 | 1.15-1.85 | 1.2-1.9 | 1.15-1.85 | 1.2-1.8 | |

| V | 0.9-1.3 | 0.95-1.35 | 0.9-1.3 | 0.95-1.35 | 1.0-1.3 | |

| Co | 7.5-8.5 | 7.5-8.75 | 7.5-8.5 | 7.75-8.75 | 7.5-8.5 | |

| Cu | ≦0.25 | -- | ≦0.25 | -- | -- | |

| 機械性質 (硬度) |

退火HB | ≦277 | ≦269 | ≦277 | ≦269 | 240-300 |

| 焠火HRC | ≧66 | ≧66 | ≧66 | ≧66 | ≧66 | |

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

- Jun 08 Fri 2012 08:55

鎢鋼圓鋸片Part2 - 鎢鋼圓鋸片偏差

繼上一篇【鎢鋼圓鋸片Part1 - 鎢鋼圓鋸片切割】,這一篇為各位介紹鎢鋼圓鋸片中鎢鋼圓鋸片偏差相關要注意的細節!

木材切削用圓鋸片在精準度要不會求太過嚴謹,但要注意,雖圓鋸片在公差規範內,若機台偏差或加工參數不當等因素,仍會造成加工NG,所以造成工件毀損不是單一面向,所以除了要求圓鋸片公差品質外,更要注意可能造成偏差的因素,盡量避免。

鎢鋼圓鋸片偏差小細節要注意:

- 內孔前磨:內孔需研磨降低表面粗糙度,這樣與機台軸心(無心研磨至鏡面)密和度高,偏差值低。

- 圓鋸片本身鋼板不夠平整問題:鋼板本身隨著外徑越大其平面研磨時,偏差值就越大,在要求精密切割時,精準度就會受到影響。

鎢鋼圓鋸片JIS規格公差規範:單位(mm)

| 外徑D | 內孔d | 刃厚度T1 | 鋼板厚度T2 | 參考齒數 | ||||

| 規格 | 容許值 | 規格 | 容許值 | 規格 | 容許值 | 規格 | 容許值 | |

| 205 255 305 355 |

±2 | 25.4 30 60 85 |

H8 | 1.8 2.0 2.4 2.8 3.0 3.2 3.5 |

±0.1 | 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.5 |

±0.08 | 24,32,40,48, 60,72,80,96, 100,120 |

| 405 455 560 610 |

3.0 3.2 3.5 4.0 4.5 5.0 |

2.0 2.2 2.5 3.0 3.2 3.5 4.0 |

32,40,48, 60,72,80 96,100, 120,140 |

|||||

鎢鋼圓鋸片JIS偏擺公差規範:單位(mm)

| 外徑 | 外周刃的擺動動容許值(最大) | 側邊刀刃的擺動動容許值(最小) |

| 205 | 0.08 | 0.15 |

| 255 | ||

| 305 | 0.10 | 0.2 |

| 355 | ||

| 405 | 0.15 | 0.25 |

| 455 | 0.30 | |

| 510 | 0.20 | 0.35 |

| 560 | ||

| 610 |

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

- Jun 01 Fri 2012 10:01

Length of the CNC lathe clamp for cutting tools?

Generally, when working project includes face cutting, outer cutting, and inner cutting three ways and rough or heavy cutting, of course we will try to extend the clamping length, and calculate the suitable pressure.

- Question (1): How to calculate the shortest clamp length without experience?

- Question (2): How to calculate the most proper clamp pressure without experience?

At first we should clarify a concept: When we machine one work piece, the first thing we should think about is “how to cut it into two halves"?

- The work piece is split in half, we must consider another important issue?

- How to fold? How long to clamp? Inter clamp or outer clamp? How to set the standard face?

We don’t need to consider above problems if we machine the work pieces of general diameter. But we must consider the wall thickness if we work inner and outer diameters (excessive pressure will cause deformation).

Sum of the above questions:

- Decided the hold surface

- The thickness of holding (diameter 2mm. the maximum pressure 1kg/cm square)

For example: the pressure of the gripping surface 15mm long (as large as will not cause any pinch) bore roughing of cut can be unilateral 4mm still will not feed 0.5mm/rev turning length up to 150mm into vibration.

There is no formula for clamping length and pressure, because too many factors to consider (like the work piece shape, cut strength and feed ....)

Suggestions are as following:

thickness unilateral 1mm which pressure is up to 1kg/cm square speed only, 800R.P.M. . the gripping surface should be above 3mm (or more).

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool, saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter production and machinery industry.

- Jun 01 Fri 2012 09:49

鎢鋼圓鋸片Part1 - 鎢鋼圓鋸片切割

鎢鋼圓鋸片是木製品加工最常用的刀具,木材是一種有纖維絲地天然資源、木料又分為有直絲與橫絲,目前合板會把直絲與橫絲交互編織做成三合板,刀具接近木料時,直紋木料就不易有毛邊,因為是直紋木料與刀具切割時成直線,所以切割不會有毛邊,但是橫紋木料與切割刀具成90度切割,木料纖維會因刀具偏擺、刀具鈍化、加工參數不正確等相關問題,而出現木料毛邊,其切割會毛邊或粗糙不外乎鋸片本身刃銳利度不夠、變形、齒形對應不當、齒數問題、機台操作參數不當、機台本身精準度…,對應不同加工材質硬度特性及切割要求在鋸片選擇上也是很重要,所以切割木料與切割金屬、塑膠、高硬度材料等材料,在刀具設計就會因客戶需求而做修正處理,當然也包括木材料的不同做調整生產刀具。

鎢鋼圓鋸片包含合金刀頭的種類、基體的材質、直徑、齒數、厚度、齒形、角度、孔徑等多個參數,這些參數決定著鋸片的加工能 力和切削性能。選擇鋸片時要根據鋸切材料的種類、厚度、鋸切的速度、鋸切的方向、送料速度、鋸路寬度需要正確選用鋸片,多瞭解刀具本身及工件、加工機台…,對於加工問題能減少效益自然就提升。

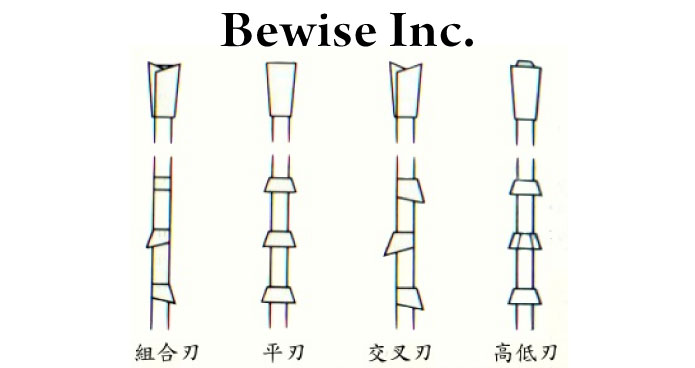

圓鋸片常見齒形:

不同的齒形不同排列組合都是針對加工上有特定作用才設計,簡單舉例,一般常見交叉齒(一左一右排列)其最基本目的是加工時較為平刃省力,切削速度快,修磨相對簡單,;另外其他排列,像切割特定需求的軟材時,交叉齒中間再排入一個三角刃形,其功用能補切割稻中間未切割到的工件…。齒排列上,交叉齒適用鋸切實木、刨花板、中密板應選左右齒,能銳利地將木纖維組織切斷,切口平滑;為了保持槽底平整的開槽,則用平齒齒形或者用左右平組合齒;鋸切貼面板、防火板一般選擇梯平齒…

下一篇將來為各位介紹鎢鋼圓鋸片中鎢鋼圓鋸片偏差相關要注意的細節哦!

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

- May 25 Fri 2012 15:08

如何讓銑刀排屑呈現片狀而且可以規定排屑長度與面積?

在切削加工中,崩碎切屑會飛濺傷人且易磨損機床, 通常排屑規範是因為在操作CNC設備加工工件時,排屑會造成工件表面刮痕,使 得工件鏡面會有刮傷,例如:長條帶狀切屑會纏繞在工件或刀具上,易刮傷工 件引發刀具破損,甚至影響工人安全等。

對於CNC機床等自動化加工機床,由於其刀具數量較多,刀架與 刀具聯系密切,斷屑問題就顯得更為重要,只要其中—把刀斷屑不可靠,就可能破 壞機床的自動迴圈,甚至破壞整條自動線正常運轉,排屑是屬於回收物料,所以通常不在 乎長度與面積大小,所以在設計、選用或刃磨刀具時,最重要是考慮刀具斷屑的 可靠性(包括工件不刮傷…)。

建議處理方式:

- 當刀具在切割工件時其溫度需控制,刀具會產生高溫讓排屑帶走高 溫,排屑會因二度高溫造成硬化,使排屑輕易刮到工件。

- 排屑會因加工路徑改變呈現出來排屑也有不同,可以利用CNC路徑 程式達到片狀切屑長度與面積相同。

- 經過專門設計銑刀也可以達到片狀切屑。

- 銑刀設計螺旋方式不同也可以達到片狀切屑。

- 銑刀設計在刀口幾何上,如OD1與OD2地不同也可以達到片狀切屑。

- 銑刀在螺旋溝底經過設計也可以達到片狀切屑。

- 在切割工件利用控制加工參數 也可以達到片狀切屑(如主軸轉述快慢,轉角設定,近幾快慢,切割深度等相關條件)。

- 複合材料切割時,要達到片狀切屑,這跟複合材料特性有相對關係 ,對應加工材料採用不同的加工方式確保斷屑可靠性。

- 利用在工件表面上的預先開槽的方法,切出的切屑形成薄弱截面,從而折斷保證了可靠的斷屑,又不影響工件已 加工表面的粗糙度。即使加工韌性較大的材料時,斷屑效果也很好。

- 利用斷屑器或斷屑裝置。

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

- May 18 Fri 2012 13:42

Definition and types of hard metal and difficult material

- Hard Material:

Generally it means higher hardness of the steel material which can be cut, such as alloy steel, die steel. . . etc.

Applicable to the cutters with coating, such as: TiAlN, TiN. - Difficult material:

It means the difficult-to-cut work piece, such as nickel-based alloys, stainless steel, etc.

Stainless steel is applicable to the cutting tools with coating like TiALN.

CBN tools is suitable to cut nickel-based alloy. - Soft material:

It means easy-to-cut cutting materials, such as aluminum, aluminum-magnesium alloy, low carbon steel, etc.

Aluminum material is applicable to cutting tools of uncoated, containing cobalt, and high helix angle.

Aluminum material is also applicable to carbide cutter.

A variety of different work materials are cut bycutting tools of different materials. However, there are lots of cutting parameters, not only material, nature, shape, and feed, etc, but also manufacturers have lots of experience and information. For those materials which are less usage or used in specific areas, the related information is less, due to less market demand and few makers’ reference data, the failure rate will be higher, so users think this material is difficult to process.

For example, aerospace materials of nickel-based super alloy INCO718 738 is well-known as very difficult work material, the general comment is” the tool is very loss."

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool, saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter production and machinery industry.

- May 18 Fri 2012 13:25

金屬鏡面加工 - part2 - 無切削方式

繼上一篇介紹去除材料方式的面加工後,本篇介紹無切削方式的鏡面加工。

無切削方式

常見加工為滾壓加工,是一種無切屑加工,在常溫下利用金屬的塑性變形,使工件表面的微觀不平度輾平從而達到改變表層結構、機械特性、形狀和尺寸的目的。因此這種方法可同時達到光整加工及強化兩種目的,是磨削、車削等機械加工無法做到且無切削加工技術安全、方便,能精確控制精度,滾壓後的表層金屬纖維完整。

在滾壓加工中常使用刀具為擠光刀,利用擠光刀機械擠壓的原理,獲得光潔如鏡的金屬表面的一種機械加工方法。擠壓刀加工是一種無切屑加工,在常溫下利用金屬的塑性變形,使工件表面的微觀不 平度輾平從而達到改變表層結構、機械特性、形狀和尺寸的目的。因此這種方法可同時達到光整加工及強化兩種目的,是磨削無法做到的。

滾壓加工原理:它是一種壓力光整加工,是利用金屬在常溫狀態的冷塑性特點,利用滾壓工具對工件表面施加一定的壓力,使工件表層金屬產生塑性流動,填入到原始殘留的低 凹波谷中,而達到工件表面粗糙值降低。由於被滾壓的表層金屬塑性變形,使表層組織冷硬化和晶粒變細,形成緻密的纖維狀,並形成殘餘應力層,硬度和強度提 高,從而改善了工件表面的耐磨性、耐蝕性和配合性。滾壓是一種無切削的塑性加工方法。

參考資料來源:百度百科

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

- May 11 Fri 2012 10:51

How do end mills choose and judge working conditions?

In recent years, machining center spindle is more and more speedy. For fitting the requirement of high speed machining on high hardness and strength materials and also prolonging mold life, the cutting tools advance its technology accordingly.

According to the processing demand, we will select the appropriate tool in accordance with the following recommendations:

- Basic cutting material of work piece, material properties, conditions, and manufacture processes….

For example: customers’ demand about size, tolerance range, result up to mirror face, corner without joint point of tool exchange, cutting path of NC program, applications, and related issues.

- To clarify different material of cutting tools (like difference of hardness and strength…)

Approx. types of cutters: single crystal diamond cutting tools, PCDs contenting CO diamond cutting tools, PCD containing Si diamond tools, PCBN cutting tools, metal porcelain cutters, tungsten carbide tools, HSS cutting tools, general steel cutters. Select proper cutting tools according to work piece.

- According to the special requirements of the work piece shape (for example: deep groove surface of work piece ...)

Generally based around the shape, surface tensile, surface rotation, ball rounded shape, conic, cylindrical curve shape, and other relevant conditions of work piece to choose the shape of end mills. The neck types of end mills are divided into standard, long-neck, and cone-neck. Select cutters according to the machining depth of the work piece, shape, appearance, processing objects, crude/middle/fine three milling paths, and other related conditions. Long-neck and cone-neck types can process deep machining, it should take into account about the interference angle during selection in both .., Compared with the long-neck type, the high rigidity of the cone neck type milling cutter may promote cutting conditions and achieve better machining accuracy, you should choose cone-neck type end mills.

- According to the machining accuracy and delicate face of work piece to select different ball head accuracy and smooth edge end mills.

The arc accuracy of ball end mills is typically ± 5μm; there are also ± 2 ~ 3μm high-precision end mills available for high-precision processing.

- According to the kinds and the hardness of the work piece to select the coating types of tools.

BW TiALN coating is suitable for machining carbon steel and hardness below HRC40 of work piece; Nano titanium aluminum nitride film-NanoTiAlN coating is for alloy steel S, tool steel, and HRC50 work piece; BW TiALN + PLCcoating. Is good for higher hardness, hard alloy material of work piece.

- If the work pieces are hard-to-cut, and special material, you should choose high hardness cutters like metal ceramic and diamond tool.

For example: if cutting metal composite material, you should choose BW metal ceramic cutter or PCBN diamond tool to solve cutting problems because the material is with high nickel content.

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool, saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter production and machinery industry.

- May 11 Fri 2012 08:42

金屬鏡面加工 - part1除材料方式

無論用何種金屬加工方法加工,在零件表面總會留下微細的凸凹不平的刀痕,出現交錯起伏的峰穀現象,粗加工後的表面用肉眼就能看到,精加工後的表面用放大鏡 或顯微鏡仍能觀察到。這就是零件加工後的表面粗糙度,過去稱為表面光潔度。鏡面加工一般是工件表面粗糙度<0.8um的表面時,稱為鏡面加工。

常見鏡面的機械加工方法有:

- 去除材料方式:磨削、研磨、拋光、電火花。

- 無切削方式(滾壓加工):滾壓(採用鏡面工具)、擠壓。

※去除材料方式

常見加工為鏡面切削,是採用運動精度及剛性高之工作母機及擁有平滑輪廓的鑽石刀具,依據母性原理從事切削加工,然後將金屬、各種結晶材料、塑膠等表面加工程鏡面的技術。利用本技術加工而成之鏡面和以往利用磨粒加工之鏡面比較時,不僅能獲得較高的形狀精度,還具有在大波長範圍內對於反射率或雷射光的耐熱損傷性也很高,同時加工成本低等特色。

由於金剛石易與鐵族金屬發生化學反應,因此不適合加工淬硬鋼等工件材料,僅局限於加工非電解鍍鎳等非鐵金屬。但近年來,由於採用超聲波橢圓振動切削的加工機床性能的改進,單晶鑽石刀具也能用於淬硬鋼等鐵族金屬的鏡面加工。 鑽石是硬度最高、導熱性能最佳的刀具材料,在難加工材料的切削加工、幹式和半幹式切削加工中刀具有很長的使用壽命且鑽石刀具能獲得非常鋒利而無凹凸鋸齒的切削刃。因聚晶金剛石粒子間的結合強度弱于單晶金剛石,因此刃磨後的切削刃也會產生晶介面的凹凸和粒子脫落現象,故常使用刀具為單晶鑽石刀具。單晶鑽石切削刀具主要用於非球面透鏡、衍射光柵高精度光學元件的加工。

參考資料來源:百度百科

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。